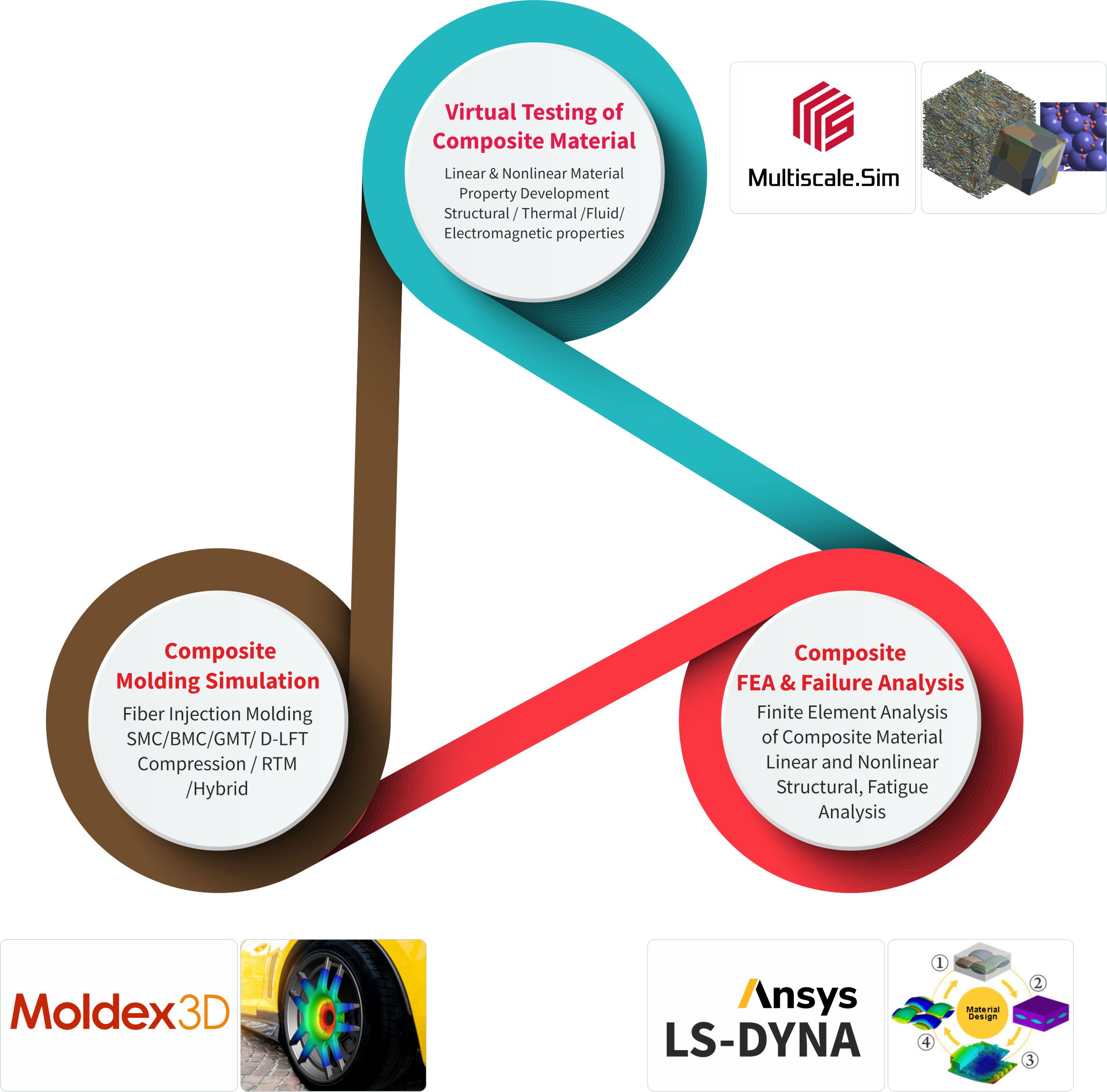

Virtual Material Testing and Characterization

Composite Manufacturing Simulation

Composite Product Design, Analysis

Composite Fatigue, Fracture Studies

Composite Ageing Simulation

Multiscale Material Modelling

Technology Partners

Composite Material Characterization, Manufacturing Simulation & Product Design Analysis

At the forefront of advanced engineering, we specialize in comprehensive composite material characterization, manufacturing simulation, and product design analysis—empowering industries to innovate with confidence. Our integrated approach spans multiscale modeling, manufacturing process simulation, and in-depth product performance evaluation, ensuring optimized designs and superior reliability.

Multiscale Material Modelling of Composites

Understanding and predicting the behavior of composite materials requires a multiscale approach—from fibers and matrix at the microscale to laminates and structural components at the macroscale. Our services cover the entire spectrum of multiscale material modeling, providing accurate insights into performance, durability, and failure mechanisms.

1. Microscale Material Characterization

-

Fiber and Matrix Property Evaluation: Determine mechanical, thermal, and viscoelastic properties of fibers, matrix, and their interfaces.

-

Interface Modeling: Study fiber-matrix adhesion, debonding, and interphase properties to predict local damage initiation.

-

Representative Volume Element (RVE) Simulations: Create detailed RVEs to capture microstructural effects and predict effective material properties.

2. Mesoscale Laminate Modelling

-

Laminate Stacking Sequence Analysis: Evaluate the impact of ply orientation, stacking sequences, and thickness on overall laminate behavior.

-

Damage Evolution & Delamination Prediction: Simulate initiation and growth of interlaminar cracks and ply-level damage under mechanical and environmental loading.

-

Thermo-Mechanical Behavior: Assess effects of temperature, moisture, and hygrothermal aging on laminates.

3. Macroscale Structural Modelling

-

Component-Level Simulation: Translate microscale and mesoscale material properties to structural analyses for beams, panels, and complex geometries.

-

Stress-Strain Predictions: Capture global deformation, stress concentrations, and failure points under realistic loading conditions.

-

Optimization: Integrate material models into design optimization for weight reduction, strength enhancement, and performance improvement.

4. Failure and Fatigue Modelling

-

Progressive Damage Modelling: Predict initiation and propagation of damage across scales.

-

Fatigue Life Prediction: Model cyclic loading effects at the micro, meso, and macro levels to estimate service life.

-

Environmental Degradation: Simulate effects of moisture, UV, temperature, and chemical exposure on long-term material performance.

5. Integration with Manufacturing and CAE Analysis

-

Process-Structure-Property Relationships: Link manufacturing-induced defects, residual stresses, and fiber misalignment to mechanical performance.

-

CAE Integration: Seamlessly incorporate multiscale material models into structural simulations for product design and analysis.

6. Advanced Computational Techniques

-

Finite Element Method (FEM), Micromechanics, and Homogenization Techniques

-

Multiscale Simulation Workflows (Micro → Meso → Macro)

-

Machine Learning-Assisted Material Property Prediction

Composite Manufacturing Process Simulation

Efficient and defect-free composite manufacturing is critical to achieving high-performance products. Our composite manufacturing process simulation services provide predictive insights into material flow, curing, residual stresses, and defects, enabling engineers to optimize processes and reduce costly trial-and-error.

1. Process Modeling and Simulation

-

Resin Transfer Molding (RTM) and Vacuum-Assisted RTM (VARTM): Simulate resin flow, filling patterns, and void formation to ensure complete wet-out and uniform properties.

-

Prepreg Layup and Autoclave Curing: Model heat transfer, resin flow, and consolidation behavior during curing cycles for thermoset prepregs.

-

Thermoforming and Compression Molding: Predict forming behavior, thickness variation, spring-back, and fiber reorientation in thermoplastic composites.

-

Automated Fiber Placement (AFP) & Tape Laying: Analyze fiber path optimization, overlaps, gaps, and defects introduced during automated layup.

2. Defect Prediction and Mitigation

-

Void Formation & Entrapped Air: Predict regions susceptible to voids, dry spots, or resin-rich areas, helping optimize injection points and venting strategies.

-

Fiber Misalignment & Wrinkling: Identify potential fiber waviness, wrinkling, or bridging during layup or forming processes.

-

Residual Stress & Warpage: Calculate thermal and curing-induced residual stresses to anticipate dimensional deviations and part distortions.

3. Curing and Thermal Analysis

-

Exothermic Reaction Simulation: Model heat generation and distribution during resin curing to prevent hotspots and incomplete cure.

-

Temperature & Pressure Control: Optimize autoclave and oven cycles to ensure uniform curing and reduce internal stress development.

-

Hygrothermal Effects: Predict the impact of moisture and temperature variations on process and final material properties.

4. Process Optimization

-

Tooling and Fixture Design: Simulate and optimize tooling layouts to minimize defects and improve production efficiency.

-

Material and Process Parameter Study: Evaluate the impact of resin viscosity, injection pressure, layup speed, and consolidation on quality and performance.

-

Cost & Time Reduction: Use predictive simulations to reduce trial-and-error prototyping, saving time, material, and production costs.

5. Integration with Multiscale and CAE Analysis

-

Process-Structure-Property Correlation: Feed manufacturing-induced variations into multiscale material models for accurate performance prediction.

-

Structural CAE Analysis: Use process simulation outputs (residual stress, fiber orientation, voids) to enhance structural analysis accuracy.

6. Advanced Computational Techniques

-

Finite Element Method (FEM) and Computational Fluid Dynamics (CFD) for resin flow and thermal analysis

-

Coupled Multiphysics Simulation for thermo-mechanical and cure kinetics

-

High-fidelity modeling for complex geometries, thick laminates, and high-performance composites

Composite Product Design, Analysis & Optimization Services

Designing high-performance composite products requires more than just material selection—it demands integrated simulation, advanced analysis, and optimization techniques to ensure durability, safety, and cost efficiency. Our services combine CAE, multiscale modeling, and predictive failure simulations to deliver reliable, optimized composite solutions.

1. Composite Product Design & Structural Analysis

-

Conceptual and Detailed Design: Support from initial concept modeling to detailed 3D design for complex composite structures.

-

Finite Element Analysis (FEA): Simulate mechanical response under static, dynamic, and impact loading conditions.

-

Stress, Strain, and Deformation Prediction: Capture critical load paths and high-stress regions for structural safety and performance assurance.

-

Thermo-Mechanical Analysis: Assess structural performance under varying temperature, pressure, and environmental conditions.

2. Failure and Fracture Analysis

-

Progressive Damage Modeling: Predict initiation, evolution, and propagation of damage at ply and laminate levels.

-

Fracture Mechanics Approaches: Apply techniques like VCCT, J-Integral, and Cohesive Zone Modeling to accurately predict crack growth and interlaminar failure.

-

Multi-Scale Failure Prediction: Incorporate microscale and mesoscale material behavior to forecast failure mechanisms in complex components.

3. Fatigue and Life Prediction

-

High-Cycle and Low-Cycle Fatigue Analysis: Model cyclic loading effects to estimate product lifespan.

-

Damage Accumulation Modeling: Track fatigue progression in composite laminates and structural parts.

-

Environmental Effects on Fatigue: Include hygrothermal, UV, and chemical exposure impacts on long-term durability.

4. Ageing and Durability Simulation

-

Long-Term Degradation Modeling: Simulate effects of temperature, moisture, and chemical exposure on material and structural integrity.

-

Creep and Stress Relaxation Analysis: Predict deformation under prolonged loads and environmental conditions.

-

Maintenance and Lifecycle Insights: Provide actionable recommendations for design improvements and preventive maintenance.

5. Design Optimization

-

Weight Reduction and Strength Enhancement: Optimize fiber orientation, ply stacking, and laminate thickness for maximum performance with minimum material.

-

Multi-Objective Optimization: Balance stiffness, strength, cost, and manufacturability in composite designs.

-

Topology and Shape Optimization: Use advanced algorithms to create innovative, lightweight, and high-performance components.

6. Integration with Material and Manufacturing Simulations

-

Process-Structure-Property Linkage: Incorporate manufacturing-induced defects, residual stresses, and fiber misalignment into product analysis.

-

Seamless Multiscale Integration: Combine microscale material behavior with macroscale structural performance for accurate predictions.

Composite Ageing Simulation Services

The long-term performance of composite materials and structures depends on their response to environmental, mechanical, and chemical degradation. Our composite ageing simulation services provide predictive insights into material and structural behavior over time, enabling engineers to design durable, reliable, and long-lasting composite products.

1. Environmental Ageing Simulation

-

Hygrothermal Effects: Simulate the impact of temperature and moisture absorption on mechanical and thermal properties.

-

UV and Radiation Exposure: Assess degradation due to ultraviolet or other radiation over time.

-

Chemical and Corrosive Environments: Model material response to exposure to fuels, solvents, acids, or other chemicals.

2. Mechanical Ageing and Fatigue

-

Cyclic Loading Effects: Predict damage accumulation and stiffness reduction under repeated mechanical loads.

-

Fatigue Life Prediction: Estimate service life under low-cycle and high-cycle fatigue conditions.

-

Creep and Stress Relaxation: Model long-term deformation and stress relaxation under sustained loads.

3. Microstructural Ageing Analysis

-

Fiber-Matrix Interface Degradation: Track interfacial debonding, microcracking, and delamination over time.

-

Matrix and Fiber Property Evolution: Model changes in material properties due to ageing, including stiffness, strength, and toughness.

-

Multiscale Approach: Link microscale damage accumulation to mesoscale laminate and macroscale structural behavior.

4. Thermal and Oxidative Ageing

-

Heat-Induced Degradation: Simulate changes in mechanical and thermal properties due to prolonged high-temperature exposure.

-

Oxidation Effects: Predict property loss and material embrittlement under oxidative environments.

-

Residual Stress Evolution: Track stress redistribution due to thermal cycles and ageing effects.

5. Failure and Durability Prediction

-

Ageing-Induced Damage Modeling: Forecast initiation and propagation of cracks, delamination, and other failure modes over time.

-

Remaining Life Assessment: Evaluate structural integrity and provide recommendations for maintenance or redesign.

-

Safety Margin Analysis: Incorporate ageing effects into design safety factors and reliability assessment.

6. Integration with Material and Product Simulations

-

Process-Structure-Property-Ageing Link: Include manufacturing-induced defects, fiber orientation, voids, and residual stresses in ageing predictions.

-

CAE Integration: Seamlessly combine ageing simulations with structural analysis and fatigue predictions for accurate lifecycle assessment.

-

Predictive Design Support: Use simulation outputs to guide material selection, laminate design, and protective measures to enhance longevity.